Ready to revolutionize your orthotics practice?

Contact us and learn more about T-Soles and our system!

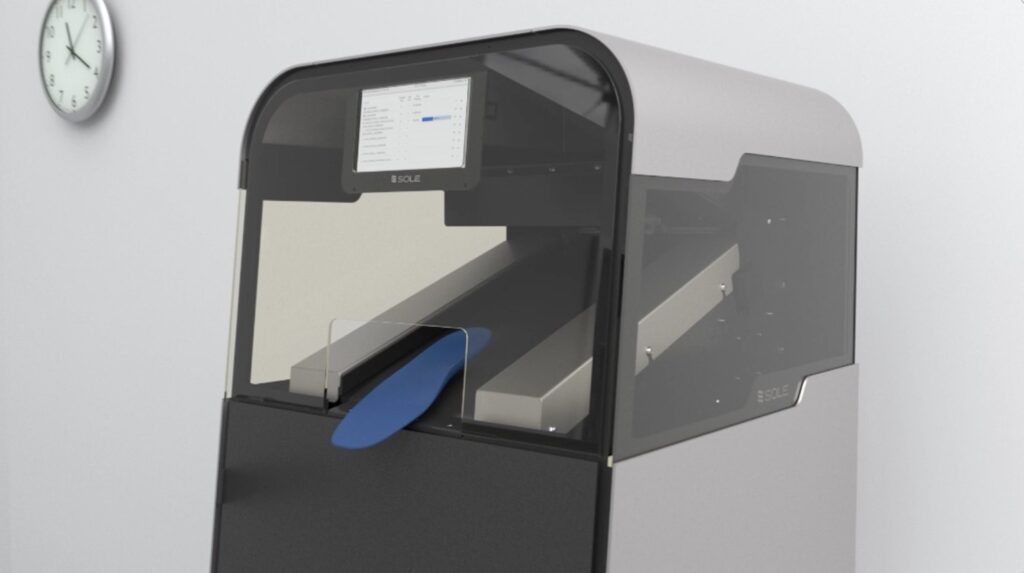

The innovative T-Soles system offers many advantages over traditional methods of insole design and production. From a 3D-CT-scan of weight bearing feet inside footwear of choice, insoles are 3D printed, taking into account the internal and external feet anatomy. This automatic process increases productivity as well as product and service quality for podiatrists. And more important, for clients this means therapeutic insoles for actual foot problems and a great increase in comfort.

No more handcraft and second guessing. Our software calculates an insole that fits the shoe and the foot perfectly!

Whether your patient is dealing with bunions, hammertoes, heel spurs, or flat feet, our extensive therapeutic library offers a variety of elements that are automatically incorporated into the insoles based on the patients pathology. The insoles come with a standardized 3 mm thickness, yet with a simple click, you can easily fine-tune the thickness and softness to meet individual preferences.

Our pressure plate enables comprehensive foot analyses, encompassing both static and dynamic measurements.

It identifies the plantar pressure profile to guide orthotic design, aids in diagnosing foot arch type, neuropathic ulcer risk areas and observe the COP line and dynamic weight transfer to check the postural stability. Our user-friendly software allows easy modifications, using standardized elements from our therapeutic library to design custom insoles for your patiënt.

Contact us and learn more about T-Soles and our system!

Visiting address

Boschdijk 1119

5626 AG Eindhoven

The Netherlands

Office address – The Netherlands

P.J. Oudweg 41 – Unit 001

1314 CJ Almere

The Netherlands

Office address – The United States of America

Copyright 2024 – All Rights Reserved By T-Soles.